About

PCX REMAINS AT THE FOREFRONT OF AEROSPACE MANUFACTURING, WITH HIGHLY-ENGINEERED, FLIGHT CRITICAL COMPONENTS & COMPLEX ASSEMBLIES FOR A DIVERSE RANGE OF MILITARY & SPACE APPLICATIONS.

WE’RE WIDELY RECOGNIZED AS A PREMIER SOURCE FOR PROPRIETARY TANKS FOR FIXED WING & SPACE APPLICATIONS & COMPLEX ASSEMBLIES, INCLUDING EXTENDABLE REFUELING PROBES, LANDING GEAR, AIRFRAME STRUCTURES & COMPOSITES.

SPECIALIZING IN LIFE-LIMITED PARTS, OUR MACHINING EXPERTISE EXTENDS TO MAIN ROTOR & POWER TRANSMISSION SYSTEMS FOR ROTORCRAFT.

QUALITY AEROSPACE MACHINING SOLUTIONS FROM COAST TO COAST

- Connecticut

- Massachusetts

- California

- Boylston, MA

- Enfield, CT

- Long Beach, CA

- Manchester, CT

- Newington, CT

- Santa Ana, CA

- Connecticut

- Massachusetts

- California

- Boylston, MA

- Enfield, CT

- Long Beach, CA

- Manchester, CT

- Newington, CT

- Santa Ana, CA

COMPLEX ASSEMBLIES, DESIGN & MISSION CRITICAL COMPONENTS THROUGH ONE TRUSTED SOURCE.

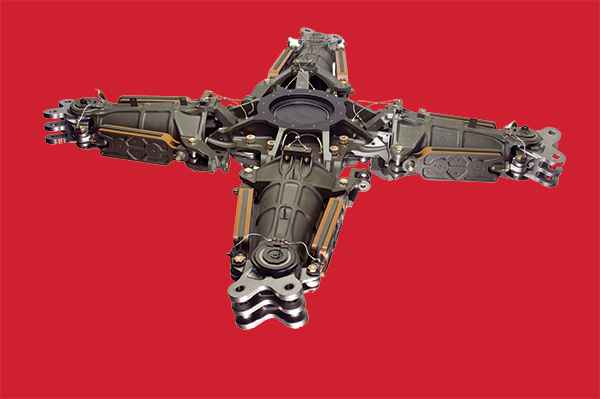

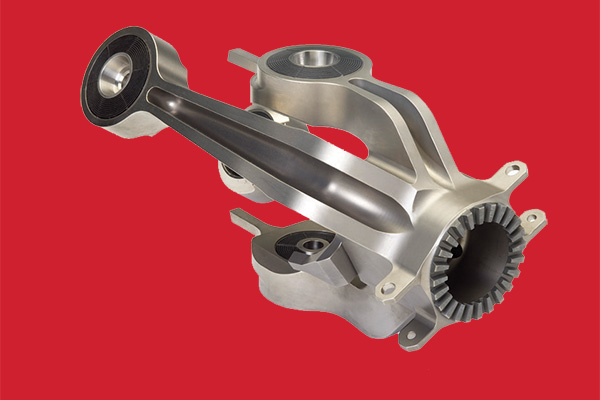

ROTORHEADS

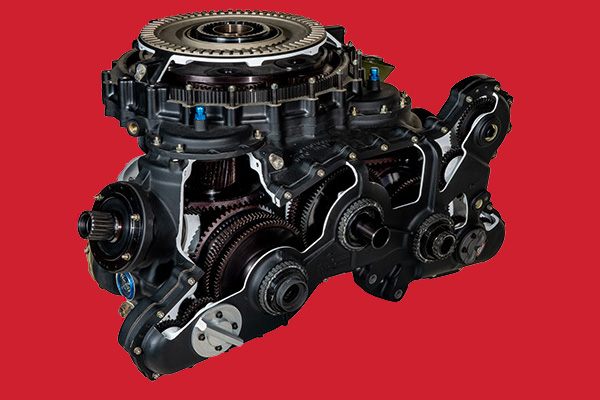

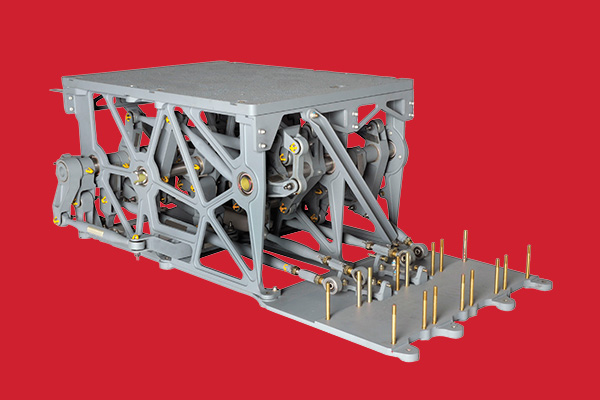

TRANSMISSION ASSEMBLIES

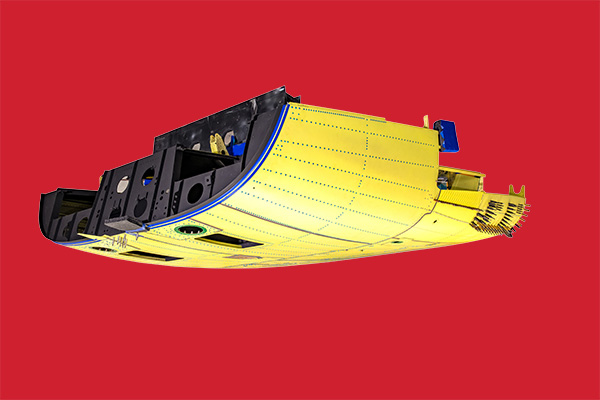

EXTERNAL FUEL TANKS

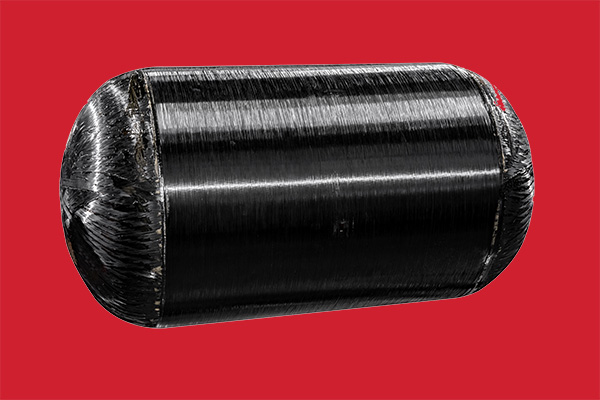

COMPOSITE OVERWRAPPED PRESSURE VESSLES (COPV)

STRUCTURAL ASSEMBLIES

LANDING GEAR

REFUELING PROBES

MECHANICAL ASSEMBLIES

MAGNESIUM & ALUMINUM HOUSINGS

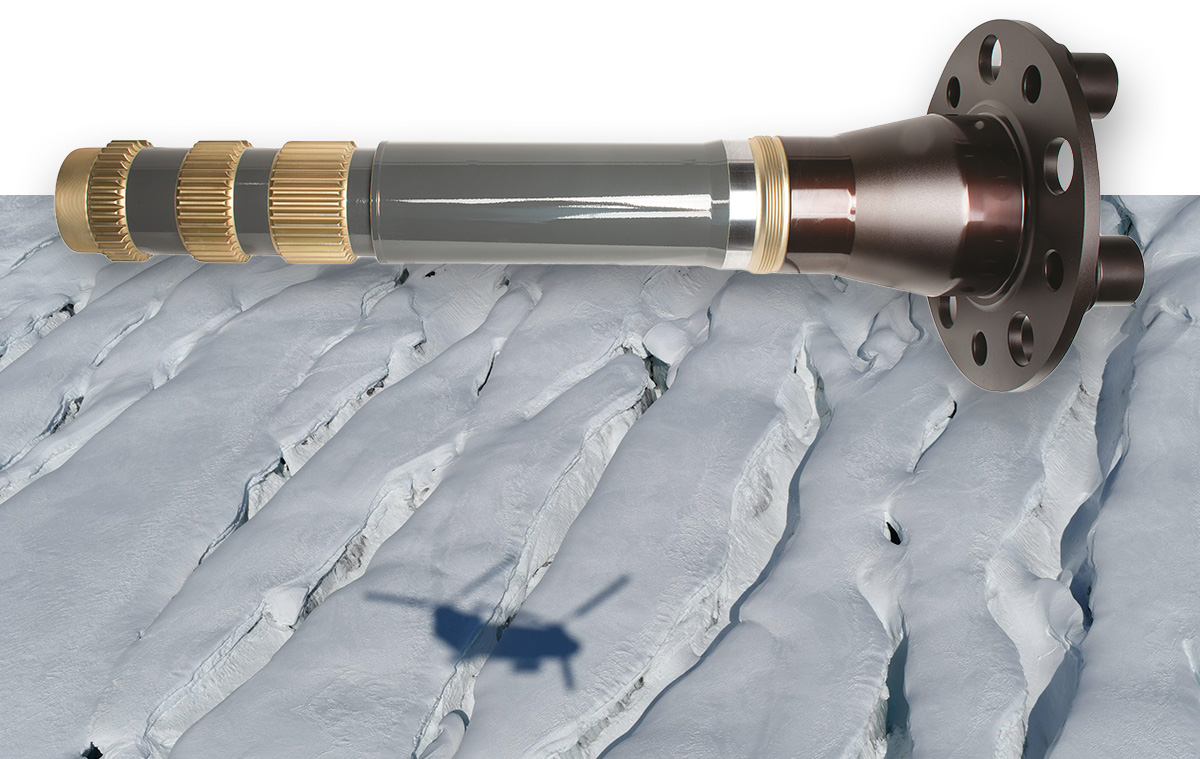

ROTORCRAFT & ENGINE SHAFTS

PRECISION MACHINING

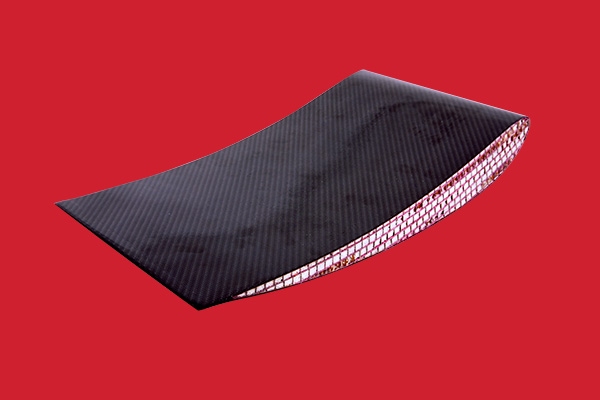

COMPOSITES

ENGINE COMPONENTS

Wilson L. Fenn, a toolmaker & machinist, founds Fenn Machinery Company in Hartford, CT, specializing in plug and ring gages.

Fenn converts traditional machining operations to 100% war-based production, including components for the notorious F4U Navy Fighter, a Chance Vought aircraft based in Stratford, CT.

Aerospace manufacturing becomes a key factor in the company’s growth due to the Korean conflict. The Company begins to manufacture rotorheads, transmissions and sub-assemblies for Sikorsky Aircraft.

Fenn begins work with Vertol (now Boeing, Philadelphia) producing rotorhead components for the Chinook military aircraft.

Fenn begins work for Hughes Helicopter Inc. (now Boeing, Mesa) producing Apache rotorhead components.

The Company celebrates its 100 year anniversary!

Charlotte, NC based SPX Corporation acquires Fenn Manufacturing.

Fenn Manufacturing rebrands as SPX Precision Components.

SPX Precision Components is taken Private and rebranded as PCX Aerostructures (later to be named PCX Aerosystems to more accurately reflect our offerings).

PCX acquired by Greenbriar Private Equity, LP

PCX acquires Senior Aerospace Connecticut located in Enfield, CT, a leading supplier of Sikorsky Flight Critical Components and transmission housings. PCX Aerosystems Enfield is formed.

PCX acquires Integral Aerospace located in Santa Ana, CA. This acquisition adds landing gear, external fuel tank systems and composite manufacturing to PCX. The company is rebranded as PCX Aerosystems – Santa Ana

PCX acquires Aero-K of El Monte, CA bringing expertise in the manufacturing of refueling boom critical components. PCX integrated Aero-K into the PCX Santa Ana facility in 2022

PCX acquires Honematic Corporation. Honematic specializes in large (up to 35ft long) gun drilling, deep hole boring, turning, milling and ID/OD honing. Products include extendable refueling boom assemblies. The company is rebranded as PCX Aerosystems – Boylston

PCX acquires Alken Industries located in Ronkonkoma, NY. Specializing in the manufacturing of complex components, this business was integrated into our Enfield location in 2023.

PCX acquires Pacific Contours in Anaheim, CA. Specializing in complex machining and large airframe sub assemblies, this business was integrated into our Santa Ana location in 2024.

PCX acquires NuSpace Inc located in Long Beach, CA. A leading-edge designer and manufacturer of proprietary propellant and high-pressure tanks for advanced satellite, launch vehicle spacecraft, and missile platforms

PCX acquires Timken Aerospace Drive Systems located in Manchester, CT, bringing a deep expertise in manufacturing, assembling, testing and refurbishing complete transmission systems and related flight safety critical gears and assemblies. Timken ADS was rebranded as PCX Aerosystems – Manchester