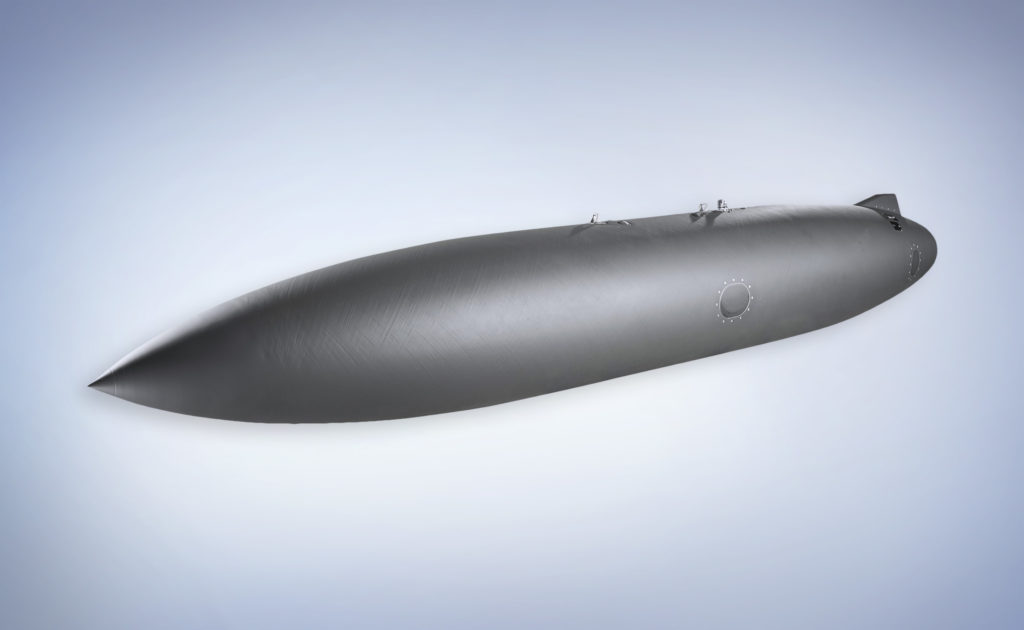

Filament-Wound Fuel Tanks & Pressurized Vessels

PCX Aerosystems manufactures custom flight-critical subsystems and components for customers in the aerospace and defense sectors. We excel at developing and applying advanced manufacturing solutions to help our customers solve highly complex technical challenges. In the spirit of continuous improvement, the team at PCX Aerosystems constantly reviews the latest advances in manufacturing techniques and materials to ensure we provide the most advanced offerings and capabilities available for our customers.

Filament winding is an open-mold manufacturing process. This method creates hollow composite forms by impregnating fibers with resin and continuously winding them around a mandrel until they reach the desired size. Our technicians at PCX Aerosystems rely on filament winding to create strong and lightweight fuel tanks and pressurized vessels.

Our Fuel Tanks & Pressurized Vessels

With more than 50 years of experience, PCX Aerosystems leads our industry as a designer and manufacturer of military aircraft fuel tanks. We’ve delivered more than 5,000 metal and filament-wound fuel tanks to the U.S. military and allied forces, and more than 250,000 all-metal and filament-wound external fuel tanks to commercial customers worldwide.

We use filament winding for composite fuel tanks and pressurized vessels for the superior control it offers in terms of fiber placement and structural consistency. The level of precision offered by filament winding is essential for serving our aerospace and defense customer base.

Our equipment portfolio includes two winders:

- Winder 1: 36” diameter x 22’ length, 3-axis

- Winder 2: 36” diameter, x 25’ length, 5-axis

Our equipment supports the production of approximately 20 external tanks per month. Typical project lead times for pressurized vessels and external fuel tanks is approximately 12 months.